Year in Review

Leaving our planet better than we found it – through ambitious action on emissions, waste, chemicals, water, and biodiversity.

Our Target for 2025:

Reduction on Scope 1 and Scope 2 emissions*

Value enhancement of non-hazardous waste

Toxic in our products and processes

Reduction in water intensities

Restoration of biodiversity in the space we occupy

*Based on 2019 baseline

^Based on 2011 baseline

Since commencing formalised environmental sustainability efforts over a decade ago, we have been constantly working to identify, analyse, and mitigate the environmental impact of our operations. Spurred by a core principle: to leave our planet better than we found it, we have extended our focus to the wider environment and community in the regions we operate.

Our Plan for Change brings together MAS’ efforts to mitigate and minimise our environmental footprint, push the boundaries of sustainability in the apparel industry, and champion ambitious and positive change at a local, national, and global scale.

Our Target for 2025:

Reduction on Scope 1 and Scope 2 emissions*

2023: 20.27%

2022: 11.48%

*Based on 2019 baseline

Our Commitment for 2025:

of our suppliers by spend and 100% of joint ventures in Scope 3 investments, will have science-based targets.

2023: 50%

2022: 36%

Climate change is one of the defining challenges of our time. We are committed to being part of the solution. In 2019/20, alongside MAS’ strategy refresh and launch of Our Plan for Change, we took a significant step forward by aligning our climate ambitions with the Science Based Targets initiative (SBTi). This translates to ambitious goals for our operations: 4.2% annual reductions in absolute emissions, toward achieving a total of 25.2% reduction against the 2019 baseline.

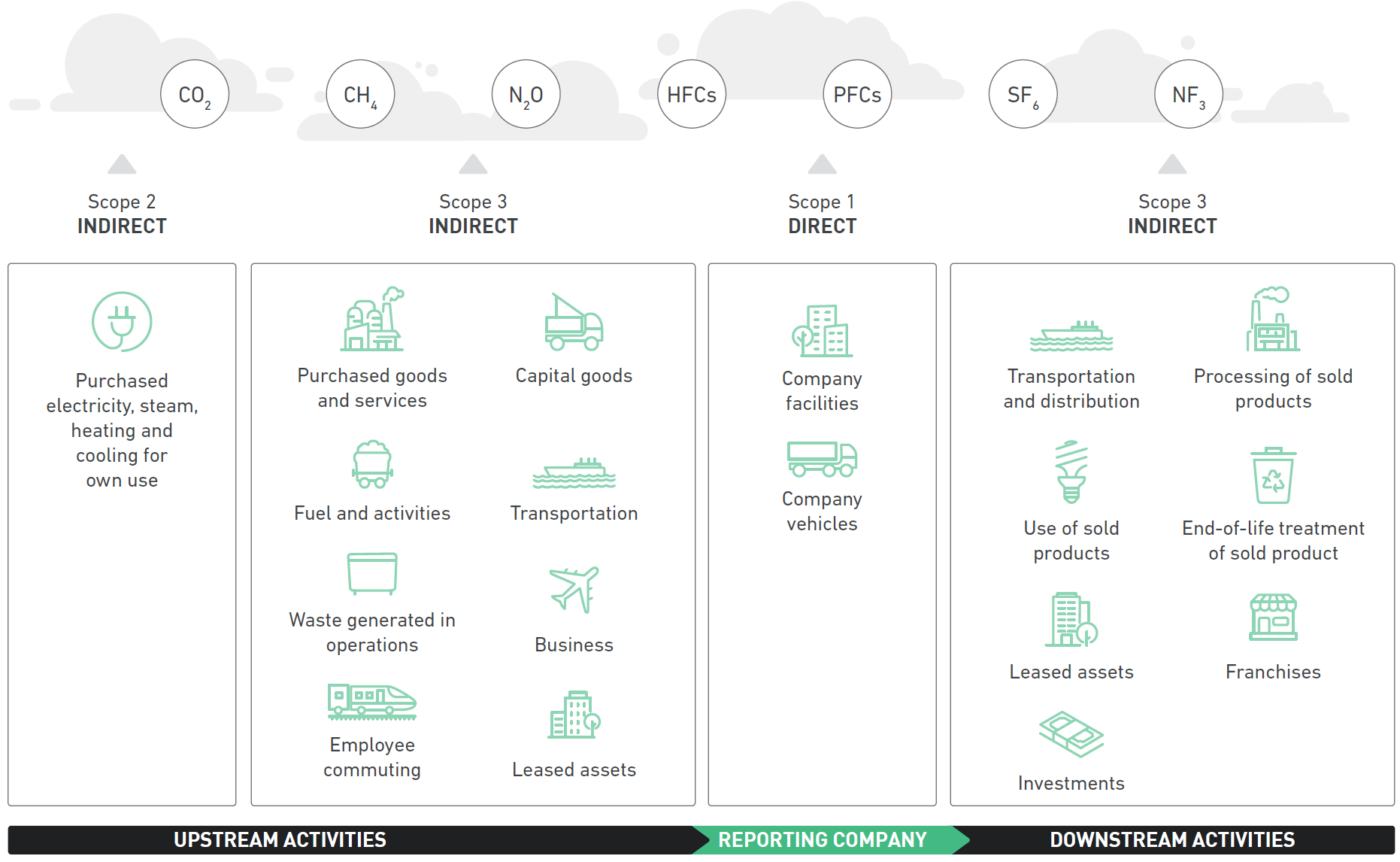

This was a herculean undertaking, considering MAS’ growth projections at the time – of operations expected to almost double in the next 5-7 years. As we set out to grow sustainably, balancing expansion with climate-conscious innovation, zero-carbon technologies and concerted collaboration across the value chain were critical to meeting our goals. As leading brands and the entire industry look to tackling climate change, Scope 3 emissions – those generated throughout the apparel value chain – hold the key to significant emission reduction.

Recognising the interconnectedness of the value chain, and the need for a comprehensive approach, our commitment to science-based climate targets extends beyond our own operations. We are actively working with suppliers and partners to set their own science-based targets, improve environmental performance, and contribute to a collective push towards decarbonisation. Our ambitious goal, validated by the SBTi, commits to 85% of our suppliers (by spend) and 100% of joint ventures in Scope 3 investments, committing alignment to science-based targets by 2025.

PROGRESS TODAY, WITH A FOCUS ON TOMORROW

In 2023, we continued a positive trajectory towards meeting emission reduction goals; achieving a 20.27% decrease in absolute emissions (Scope 1 and Scope 2), against our 2019 baseline.

We saw significant progress in emission reduction, across all Scopes, during the year. Gains were made possible by renewable energy generation through Project Photon (rooftop solar that resulted in 12,269 MTCO2e annual emission reduction); sourcing and utilisation of sustainable and carbon-neutral biomass; and ongoing energy efficiency improvements across our operations. However, some of our emission-reduction in 2023 is also attributed to business scale-down; which may not continue into proceeding years.

We also made significant progress against our target for the supply chain and Scope 3 emissions: Supply chain engagement increased during the year, and approximately 50% of our suppliers by spend have now committed alignment to science-based targets for emission reduction.

In terms of energy and emissions-intensity, our Apparel Manufacturing operations recorded an energy intensity of 19.18 MJ/SH and emissions-intensity of 1.002 KgCO2e/SH. Our textile production operations maintained an energy intensity of 161.22 MJ/kg and emissions-intensity of 10.586 kgCO2e/kg, during the year.

| 2019 | 2020 | 2021 | 2022 | 2023 | |

| Target emissions (TCO2e) | 168,832 | 161,741 | 154,650 | 147,559 | 140,468 |

| Actual emissions (TCO2e) | 168,832 | 137,382 | 156,420 | 149,446 | 134,604 |

| Expected reduction (%) | 4.20 | 8.40 | 12.60 | 16.80 | |

| Actual reduction (%) | 19.00 | 7.40 | 11.48 | 20.27 |

Scope 1 |

Scope 2 |

Scope 3 |

|

| What it entails | Direct emissions from use of biomass and on-site fossil fuels in our equipment, machinery, and fleet. | Indirect emissions as a result of purchased electricity, heat, and steam that power manufacturing operations and ancillary functions. | Emissions across the value chain: Primarily as a result of extraction, processing, and transport of purchased raw materials upstream; waste generation in operations; and downstream distribution, use, and end-of-life treatment/disposal of apparel we manufacture. |

| The challenge | Cleaner sources like bioenergy come from a largely unregulated and informal biomass industry, which poses sustainability risks surrounding feedstock production and availability. | Energy-intensive processes, and systemic/structural limitations of energy-providers who rely on fossil fuels for energy-generation. | Quantifying emissions and identifying hotspots across a broad supply chain, remains challenging. This is compounded by varying and evolving methods for assessment, data collection, and verification. Achieving concrete emission reductions requires concerted, collaborative efforts from both upstream and downstream entities, and relies heavily on market forces, global regulation, and technological advancement. |

| Our response | Responsible sourcing and use of biomass is ensured through the Group’s Sustainable Biomass Standard; developed in line with international best-practices and local adaptations Prioritising fast-growing, sustainable fuelwood – such as Gliricidia, presents an innovative solution to GHG reduction. | MAS continues to scale-up renewable energy generation and consumption – through investments in solar, initiation of PPAs, and purchase of RECs and iRECs. We are in the process of claiming iRECs for the Group’s large solar generation footprint in Sri Lanka, which would unlock further reductions. Stringent energy management and ongoing energy efficiency gains are also driving emission reduction. | Our Plan for Change includes an ongoing commitment to waste transformation, innovation, circularity, and sustainable sourcing. These hold great potential for decarbonisation across a range of areas, including elimination of waste; innovation and design for product longevity and closed-loop solutions at end-of-life; and groundbreaking partnerships sourcing alternatives to fossil-fuel based or virgin raw materials. |

| Where we are today | 46,289.32 TCO2e 34% of Scope 1 + Scope 2 emissions |

88,315.21 TCO2e 66% of Scope 1 + Scope 2 emissions |

2,171,336.49 TCO2e |

Scope 2 emissions account for the majority (approximately 66%) of MAS’ total emissions from operations. This is an ongoing structural challenge for MAS and the wider industry since the high share of emissions is directly related to emission-intensive components of manufacture, such as wet processing, which require large amounts of energy and traditionally utilise fossil fuels onsite.

Purchased electricity represents a hard-to-abate component of our carbon footprint, as energy providers in our countries of operation are still largely dependent on fossil fuels for energy generation.

However, MAS’ decarbonisation efforts through signing Power Purchase Agreements (PPAs) and obtaining Renewable Energy Certificates (RECs) from major energy-providers, such as Indonesia’s state-owned energy provider – PT Perusahaan Listrik Negara (PLN), are boosting the share of clean energy purchased. Similarly, for heat and steam purchased from managed facilities, such as MAS Fabric Park, the shift to sustainable biomass continues to reduce Scope 2 emissions.

Biogenic CO2 emissions, related to use of biomass, accounts for the second largest share (approximately 29%) of our total emissions. Biomass is a viable clean alternative to coal, when sourced and managed sustainably, and is an important element in our pursuit of carbon-neutral energy sources and scale-up of zero-carbon technologies. In 2023, sustainable biomass was introduced to our energy mix, as a GHG reduction initiative, through a project with Lanka Biofuel Solutions (LBS).

The following section, on our Holistic Approach to Decarbonisation, describes MAS’ sustainable, transparent, and traceable strategy for sourcing and utilising biomass; and details our proactive partnerships and ventures to reduce both Scope 1 and Scope 2 emissions.

Considering the critical importance of decarbonisation for the entire apparel industry, we have extended our assessment of Scope 3 emissions to cover the entire lifecycle of our products – from cradle to grave. This takes into account all 15 categories outlined in the GHG Protocol guidance on accounting for emissions across the value chain. We also undertake verification and validation of our GHG accounting methodology and disclosures; carrying out audits to meet the ISO 14064 standard.

Assessment and quantification of our Scope 3 emissions show that the downstream use-phase of our products constitutes the majority of our emissions (45%) along the value chain; while the end-of-life phase (including end-of-life treatment for apparels), contributes an additional 3%. Purchased goods and services account for the second largest share (35%). These are upstream emissions primarily related to the extraction, processing, and production of raw materials used in the apparels we manufacture. Additionally, transport and distribution of both raw materials and finished products; comprises about 12% of our total Scope 3 emissions.

Life cycle emissions across the value chain can vary significantly; according to the composition and design of products, channels of distribution, usage patterns of consumers, and disposal options. However, our assessments, and studies by independent bodies, manufacturers, and retailers alike; point to raw material production and use-phase of apparels as primary emission hotspots. This is where our product innovation and disruption, pioneering of circularity, and sustainable sourcing practices can all lead to transformative change in the long-term.

As part of our environmental management protocols, we regulate and monitor the quality of all air emissions from our facilities in compliance with local regulations and international best practices. While our operations do not use Ozone Depleting Substances (ODS) for primary processes, products, or services, we account for the presence of hydrochlorofluorocarbon (HCFC) in Heating, Ventilation, and Air-Conditioning (HVAC) systems. Our efforts to phase-out ODS are aligned to regulator-driven stipulations in the areas we operate, including Sri Lanka where HCFCs are planned to be phased out of the market by 2030.

| 2023 | |

| Ozone Depleting Substances (ODS) (TCO2e) | 2,061 |

| Carbon Monoxide (CO) | 84% |

| Nitrogen Dioxide (NOx) | 4% |

| Sulphur Dioxide (SOx) | 5% |

| Volatile Organic Compounds (VOCs) | 0.03% |

| Particulate Matter (PM) | 7% |

MAS’ efforts to achieve an absolute reduction in carbon emissions, in line with SBTi commitments, necessitates systemic and structural change across the Group’s entire operational footprint. Therefore, we take a holistic approach to decarbonisation guided by Our Plan for Change, which functions as a forward-looking blueprint that synergises our efforts.

At a micro-level, we monitor energy and carbon intensity by division and activity. This empowers Senior Management, engineering, and sustainability teams to make informed, timely, and strategic decisions that keep our decarbonisation efforts on track. We calculate the carbon footprint of our operations on an annual basis, and work with an independent third-party - the Sri Lanka Climate Fund, operating under the ambit of Sri Lanka’s Ministry of Environment, for verification.

Managing emissions in the textile and apparel value chain is complex; with factors like product design and composition, sourcing strategies, intrinsic energy-needs of processes, structural and technological limitations in production, and systemic challenges associated with energy sources of different countries and geographies, all affecting emission intensity. Despite these complexities, MAS has made significant progress by transforming systems, processes, and activities. Our stringent energy management, structural changes to energy-mix, and focus on operational excellence; all contribute to long-term emission reduction in carbon intensity of our production processes.

In 2023, the average carbon intensity of our Apparel Manufacturing operations, (cut and sew) was 1.002 kgCO2e/SH, and our Textile Production operations recorded a carbon intensity of 10.586 kgCO2e/kg.

Scope 1 and Scope 2 |

Scope 2 and Scope 3 |

Scope 3 |

||

| Energy transition | Transforming waste | Innovation

(product and process) Products changed for good – Innovate and Disrupt |

Circular thinking Products changed for good – Pioneer circularity at scale |

Sustainable sourcing Products changed for good – Source sustainably |

| Sustainable sourcing and utilisation of biomass. Scaling up renewable energy generation. Practicing sound energy management: maximising energy efficiency and saving. | Valourisation of non-hazardous waste (recycling and resource-recovery, and energy recovery). Responsible and proactive hazardous waste management (treatment, pre-treatment, repurposing, and energy recovery). | Product innovations unlocking increased resource efficiency; utilising climate-positive raw materials; and reducing waste. Process innovation that contributes to resource and energy optimisation. | Partnering across the value chain to support closed-loop solutions that address end-of-life impact of apparels. Incorporating circular design for apparel longevity, durability, and recyclability. | Collaborating with suppliers to reduce emissions. Sourcing renewable materials and alternatives to fossil fuel based inputs. Implementing traceability that is supporting recycling. |

The apparel industry is undergoing a critical shift towards cleaner energy sources, and addressing dependence on fossil fuels throughout the production chain. Our ethos of striving for change, and long-standing climate and sustainability initiatives have tackled this head-on.

GHG reduction initiatives and projects, such as the Group’s Solar PV footprint – which generates and sells electricity to the national grid; Power Purchase Agreements (PPAs) with energy-providers; and purchase of International Renewable Energy Certificates (iRECs); have contributed to an estimated emission reduction of 27,330.83 MTCO2e during the year.

Bioenergy, obtained from biomass, comprises a renewable and clean energy source that powers a significant portion of our operations. While combustion of biomass does contribute to emissions, the feedstock (source plants) for biomass can sequester almost as much CO2 during their growth-phase, as they emit when combusted; making it potentially carbon-neutral. We take a proactive and responsible approach to sourcing and utilising biomass in our operations, with stringent measures in place to record purchases and ensure traceability. In regions where the biomass industry lacks regulation, MAS has been at the forefront of promoting sustainable practices in the sector.

In Sri Lanka, we have consistently engaged with regulators and suppliers to drive sustainability in the industry. We supported development of a sustainable fuel-wood standard for the country, which included criteria for sustainably produced fuel-wood that prioritised both environmental and social factors. Our innovative approaches, including use of invasive plants as biomass, resulted in lower energy intensity, while contributing to conservation of vulnerable ecosystems. MAS’ sustainable biomass standard for operations, specifies suitable climate-neutral feedstock, incorporates systems for sustainable sourcing, and ensures certification and verification that prevents deforestation and biodiversity loss.

MAS’ emissions reduction and climate ambitions are powered by pioneering projects like Project Photon, a multi-roof solar installation initiative.

Project Photon is the evolution of MAS’ long-term journey to expand the use of renewable energy. From our very first solar installation in 2008, at MAS Intimates Thurulie - the world’s first purpose-built LEED Platinum Certified Apparel Factory, to South Asia’s largest solar installation in 2015 – 1MW at MAS Matrix; we have been at the forefront of pursuing renewable energy with a legacy of early-adoption.

Today we have an installed capacity of 23 MW across 25 rooftops – in Sri Lanka. Project Photon comprises Sri Lanka’s largest solar roof area, generating clean energy exported to the National Grid and providing additional supplementary income. The Project reduces our annual carbon footprint by an estimated 12,269 tons of CO2e and together with other sources of renewable energy such as sustainable biomass, iRECs, RECs, and PPAs; contributes to around 33% of MAS’ energy consumption coming from renewable sources.

Photon also serves as the first and largest comprehensive network of weather monitors providing real-time and historical data on solar irradiance (sunlight intensity). Contributing to research and informing future investments in renewable energy.

Partnering with energy providers through Power Purchase Agreements (PPAs) and procuring clean energy through partners possessing verified Renewable Energy Certificates (RECs), helps mitigate our reliance on fossil fuels.

MAS Indonesia is an exemplar in this regard. A partnership in place with the state-owned electricity provider – PT Perusahaan Listrik Negara (PLN), sources 100% of the energy needs of our facilities from renewable sources such as the Kamojang Geothermal Power Plant. This agreement covers four MAS facilities in Indonesia: MAS Arya 1 and MAS Arya 2, PT Silueta Indonesia, and Prym Intimates Indonesia.

Facility-wide energy management is made possible through the Schneider Energy Management System (EnMS), a powerful tool that provides real-time data on electricity and water usage across our operations. The system empowers MAS energy managers and engineering teams to analyse historical data and monitor trends, identify areas for improvement, and make informed decisions about capacity utilisation, maintenance, and other elements essential to production. The system optimises energy use, improves process control, and facilitates predictive maintenance; reducing downtime and operational costs. Achieving the net effects of reduced energy consumption, lowered emissions, and improved regulatory compliance.

Our Target for 2025:

Value enhance of non-hazardous waste

of all waste value enhanced by recycling, reusing, upcycling or utilising in waste to steam conversion for internal process use in 2023

2022: 63.8%

As a leading apparel manufacturer, working with pioneering global brands, we are at the forefront of developing innovative, effective, and sustainable solutions to the apparel industry’s waste footprint. Our vision is to transform waste into a valuable resource, giving it new life, creating value, and also minimising and mitigating environmental impact.

As part of the MAS Plan for Change, we have set ourselves an ambitious goal: to achieve 100% value enhancement for all non-hazardous waste generated through our manufacturing processes, by 2025. To achieve this goal, we employ Group-wide efforts for waste minimisation; engage with third-party waste management partners to ensure safe and responsible disposal; and devote resources to continuous innovation and collaboration – both imperative to address the impact of waste across the life cycle of our products.

Waste Transformation through Continued Action

Working towards 100% value enhancement of all non-hazardous waste by 2025; we made progress during 2023, achieving 70.5% of all non-hazardous waste value enhanced. Up from 63.8% the previous year. This progress is achieved by concerted and continuous action across our operations. In 2023, initiatives for process optimisation, innovation, collaboration, and capability development were the drivers of our success.

We continued to uphold an ongoing commitment to zero landfilling across our operations, achieving 99.3% of all waste diverted from landfills during the year. The remaining 0.7% was directed to government-authorised landfills and disposed responsibly. Our facilities in Sri Lanka, Bangladesh, India, Vietnam, and Jordan, have practised zero landfilling since 2021, and 100% of Raw Material (RM) waste from our global operations is diverted from landfills.

All hazardous waste was diverted from landfills and disposed responsibly, In line with environmental regulations, through energy recovery. A minimal portion of hazardous waste was value enhanced through preparation for reuse or recycling.

Addressing our non-hazardous waste footprint, actions focused on the processes and people involved in our operations. We took steps to increase cutting table efficiency on the shop-floor; continued to monitor progress against group-wise KPIs for waste recycling and reuse; carried out training for waste-handlers; and maintained engagement and collaboration with third-party waste management partners. Similarly, ongoing projects to adopt paperless processes and carry out waste segregation at department level, helped reduce our footprint and better manage the non-RM waste we generate.

Our innovation and circularity teams continued to pursue avenues for scaling of synthetic and natural fibre recycling, and reincorporation of post-consumer waste. Achievements in this arena are described in the Products Changed for Good section. In 2023, we strengthened relationships with textile to textile recycling technology providers, and laid the groundwork for piloting of commercial-level initiatives around circularity from 2023 onward.

To gain a comprehensive understanding of our waste footprint, we carry out waste flow analyses to categorise and analyse waste streams based on their origin (production activity/function in the value chain), composition, and classification. All percentages represented below are approximate values based on 2022 figures, but are largely unchanged year-on-year, and representative of waste streams structurally inherent to our operations.

| Origin | Composition | Classification | Waste management measures |

| Apparel manufacturing (cut and sew operations) | Stream 1: Categorised as Raw Material (RM) waste, makes up approximately 69% of non-hazardous total of total waste

from our operations. Primarily consisting of (47%) raw material

reuse and recycle of raw material total. Stream 2: Non-RM waste, makes up around 27% of non-raw material non-hazardous total of total waste from our operations. Composed primarily of reusable or recyclable packaging components and materials and Municipal Solid Waste (MSW), which includes food waste. |

Non-hazardous (96% of waste that falls within our operational boundary) |

Majority of non-hazardous waste is value enhanced through a variety of means, including recycling; upcycling/downcycling; repurposing and reuse on the factory floor or via community engagement; and waste to steam (W2S) generation on-site – which constitutes a cleaner source of energy, compared to conventional incineration.

|

| Textile production | Largely consists of process chemicals and effluent sludge generated at facility level, and fabric and other materials contaminated by contact with chemicals. | Hazardous (4% of waste that falls within our operational boundary) |

Almost all hazardous waste generated, is directed to disposal for incineration with energy recovery. This is in line with industry best-practices and environmental regulations in our areas of operation.

|

The issue of waste in the apparel industry is two-fold. While post-consumer waste is often the most visible; upstream pre-consumer waste, generated during production, also presents a substantial challenge that requires effective management to reduce environmental impact. As with most environmental challenges, the solution to waste is complex, interconnected, and requires a holistic approach. This is why our commitment to transforming waste extends to finding solutions for both these, with an ultimate focus on the entire apparel value chain.

As an apparel manufacturer, our waste management efforts focus on the production process, but they don’t stop there. We are also committed to responsible management of indirect waste generated by our business, our people, and our communities.

When addressing waste management solutions, we adopt a lifestyle perspective. This approach considers upstream raw material extraction, and downstream circulatory opportunities, such as prioritising recycling and reuse, ensuring a comprehensive cradle-to-grave perspective.

Adopting the 7R principles, we actively work to prevent and reduce waste as a fundamental imperative. This begins with our plants, and the practices of our people.

Practices: With over 75,000 employees based in Sri Lanka, we recognised the potential for significant impact in adopting innovative waste management practices across our national footprint, which could be modelled and replicated across other regions. To this end, MAS launched the “Pirisidu Lanka” initiative (which translates to “Clean Lanka”) in 2020. This waste management process sets out a series of guiding principles for our facilities; promotes innovative solutions to reduce, reuse, and recycle non-manufacturing waste; develops staff capabilities on waste value enhancement; improves waste management infrastructure at our facilities; and creates model plants that uphold zero landfilling. The project also extends to initiatives within the community, as described in the section ahead on “Inspiring Change beyond our Walls’.

Group-wide and facility-level waste policies provide further contextualised guidance while stipulating strict standards to be met. KPIs for SBUs and Divisions, which promote recycling, reuse, and value enhancement of waste, serve to instill best-practices and support operationalisation of policies.

Processes: Addressing waste directly related to our primary production processes, textile production/fabric processing and apparel operations (cutting, sewing, and finishing), we incorporate practices and processes for both waste reduction and waste value enhancement. From incorporating strategic lean manufacturing principles and maintaining oversight through the MAS Operating System (MOS) and ERP system; to Group-wide initiatives such as paperless processes, and optimisations rolled-out on the shop-floor; we keep waste to a minimum.

While maintaining a commitment to zero-landfilling, all hazardous waste is suitably treated and disposed responsibly – primarily through energy recovery. With regard to process chemicals with potential waste-related impacts, our waste management processes include co-processing and safe measures for disposal or return.

At the same time, guided by the philosophy of waste transformation, MAS is constantly innovating and looking for new avenues to value enhance the waste that is generated. A significant portion of non-hazardous, non-RM waste, is either reused on the factory floor itself, or recycled. In line with customer guidelines and local regulations, suitable fabric waste is recycled, upcycled or downcycled. Where current technological and cost factors limit recycling at scale, such as with 95/5 polyester-spandex, we leverage MAS’ robust community engagement programmes to repurpose, reuse, and recycle non-hazardous fabric waste. Many of these initiatives are creating jobs and strengthening the livelihoods of communities in the areas we operate. Where intellectual property, confidentiality, and brand protection guidelines dictate; fabric waste is directed to energy recovery through incineration.

As a Group, we uphold a commitment to reduce and eliminate landfilling across our operations. Success of our multi-layered strategy has ensured that 100% of our RM waste is diverted from landfills. Similarly, non-manufacturing waste, including Municipal Solid Waste (MSW) generated at our facilities is also introduced to value enhancement wherever possible. We work to minimise, manage, and recycle or repurpose MSW; which primarily comes from canteen operations and other employee activities. The Pirisidu Lanka programme, now rolled out across our global operations, directly addresses MSW generation by reducing generation at source. However, inevitably, a small portion of MSW ends up in landfills because of limitations to further segregation or value enhancement.

These waste enhancement initiatives are built around a rigorous process for monitoring and managing waste across all facilities. This system begins with point-of-origin segregation, where different waste types are separated at source. All waste is then stored in designated areas, with specific locations for both hazardous and non-hazardous materials. To ensure accurate tracking, waste-handlers ensure weighing and documentation at each waste stream. Data is fed into an internal monitoring system, allowing for group-level waste analysis on a monthly basis. Finally, to guarantee integrity of the process, annual plant audits are conducted to verify standards for waste management and data collection are upheld.

Partnerships: Apart from Waste to Steam (W2S) initiatives for energy recovery, that are carried out on-site, all waste generated through manufacturing and other processes, once segregated and recorded, is collected and managed by third-party waste management suppliers. Therefore, exercising due diligence, ensuring close monitoring, and developing enduring partnerships with our suppliers, are key to the success of waste enhancement initiatives. Suppliers are selected based on annual evaluations, which account for environmental and waste management licenses, disposal methods, and best-practices. At all times, we strive to work with waste management partners who are innovative, responsible, and compliant with local and international regulatory requirements.

We employ life cycle thinking and Life cycle Assessments (LCAs) in order to identify potential impacts of post-consumer waste, and map our role in driving solutions. Taking a cradle-to-grave perspective, we analyse the use-phase and end-of-life waste-related impact of products we manufacture. With the MAS Plan for Change as a platform, we then devise and roll out strategies that ensure we are well placed to partner across the value chain and deliver innovative solutions that mitigate these impacts.

Over the last few years, we have invested in training key personnel on conducting LCAs; allowing us to design and merchandise products in a far more sustainable manner, with consideration for end-of-life of manufactured products. Guided by our product approach, described in Products Changed for Good , and the MAS Sustainable Product Criteria and Rating System, we deploy an innovative multi-modal strategy to address post-consumer waste.

Assessing potential downstream waste-related impacts of our product outputs, we emphasise circular thinking and Priority Raw Materials (PRM) management strategies that are cognisant of waste-related risks. Our systems for waste reduction, value enhancement of difficult-to-manage materials, innovations to substitute hazardous chemicals, and ethical sourcing of sustainable materials; all contribute to mitigating potential downstream impacts, while creating novel opportunities for closing the loop and promoting circularity in the industry. The section on pages Products Changed for Good to Lives Changed for Good describes how we are Pioneering Circularity at Scale; through a number of partnerships with innovative customers, raw material producers, collectors and segregators, recyclers, and logistics providers.

MAS’ vision for waste transformation extends beyond our operations. We are able to extend our waste management efforts to communities and the countries in which we operate, through division-led community-based initiatives, groundbreaking programmes driven by the MAS Foundation, and partnerships with leading technology innovators.

Single Use Plastic Elimination Project at Mihintale Temple

MAS Kreeda spearheaded a project to make Mihintale Temple a single-use plastic-free zone in preparation for the Poson Poya celebration in 2023. This initiative brought together more than 25 stakeholders, including government officials, private sector entities, non-governmental organisations, educational institutions, community organisations, and the broader community, engaging over 5,000 participants.

The project kicked off with a major clean-up day involving all stakeholders to assess current waste management practices. During this initial clean-up, more than 1,000 PET bottles were collected from the Meda Maluwa and upper areas. The effort required over 20 semi-truck loads to haul away the waste. Following the Poson Poya celebration, only 20 PET bottles were found in the upper area of Meda Maluwa during a subsequent inspection, and just four semi-truck loads of waste were collected on the second clean-up day. A key component of the project was the establishment of a waste management plan for the Poson period. This plan included strategically placing waste bins, implementing a regular waste transport system, and eliminating the use of plastic items at the temple.

Our Target for 2025:

toxic in our products and processes

of MAS Chemicals at ZDHC MRSL Version 3.1 Level 1 or above accepted status in 2023

2022: 99.8%

Our commitment to responsible chemical use considers potential environmental impact, employee health and safety, and consumer safety. The goal to be zero toxic by eliminating harmful chemicals from our products and processes is not a point-in-time destination; but an ongoing process.

As science continues to shed light on the environmental and human impact of anthropogenic processes and materials; regulations, industry practices, and consumer preferences are also evolving. Our efforts, to streamline chemical management within our facilities, collaborate with chemical suppliers, and uphold transparency through verification and certification; are building confidence for customers working to eliminate harmful chemicals from both their products and the wider apparel value chain.

MAS’ robust chemical management process supports responsible use of chemicals not only at our facilities, but also across the supply chain. We benchmark our operations and supply chain facilities against internationally recognised standards such as the Zero Discharge of Hazardous Chemicals (ZDHC) initiative, Bluesign, and Higg FEM; covering the areas of Input, Process, and Output.

The section on Ambitious Targets, Real Change (Our Plan for Change page) has more details on what our certifications mean, where they align with international regulatory standards, and how they are making apparels safer and more sustainable.

In 2023, we achieved 88% ZDHC MRSL compliance for chemicals used in our Textile Production processes and facilities. This is a 12% decrement compared to the previous year, which reflects measurement against the updated MRSL Version 3.1, rolled out in late 2022, wherein several new restrictions were introduced. Our facilities are in the process of renewing certificates from 2.0 to 3.1, within the allocated transition period.

In 2022 we made a strategic decision to align the chemical management process of our Textile Production operations, including compliance of wet operations, with Bluesign; one of the most stringent global sustainable chemical certification. In 2023, our dye facilities have successfully transitioned to using 94% Bluesign approved chemicals within their operations.

Achieving Bluesign certification for our articles means we are not only minimising environmental impact at the manufacturing stage, but also enabling customers to expand their sustainable product portfolio and offer consumers with safer, more environmentally-conscious choices.

The capacity and awareness of our teams is an essential component in ensuring responsible chemical use across input, process, and output. In 2023, we continued to invest in employee capability, with over 15 trainings conducted for employees at different levels, covering topics like Safety Data Sheets (SDSs), safe handling practices and proper disposal methods, and emergency readiness, for direct handlers. Additionally, nine separate trainings were conducted for our executive teams, providing essential knowledge on industry standards like ZDHC MRSL, RSL, Bluesign, and the Group’s chemical management tools in place.

Extending our oversight to the value chain, we monitor input chemical compliance and ZDHC Wastewater compliance for 42% of our spend base. Working with upstream chemicals suppliers and embellishment subcontractors continued to be a priority in 2023. We held forums for local chemical suppliers and subcontractors to communicate progress against our sustainability targets, Group expectations, evolving compliance requirements for 2023, and progress on certificate renewals.

Our approach to chemical management focuses on three key areas: Input controls that ensure the chemicals we purchase and use, are safe; Process controls to enable safety in handling, transport, labelling, use, and storage of chemicals; Output controls and verification that guide how we treat and dispose of chemical waste and industrial effluent, ensure environmental compliance, and guarantee safety of the products we manufacture. Product Stewardship at MAS involves a commitment to safety and conformity of the apparels we produce. This is ensured through collaboration with customers, finished product testing, third-party audits, and certification against international standards.

The Group’s Central Sustainability Team guides facilities toward achieving our goals for responsible chemical use, including chemical management; backed by a comprehensive Group-wide chemical management policy and manual. Within this framework, divisions and Strategic Business Units (SBUs) follow brand-specific chemical management guidelines, while ensuring they are in keeping with the Group’s overarching chemical policy requirements.

|

Input

|

Process

|

Output

|

||

|

Supply Chain

Collaborating with RM suppliers and subcontracting partners, to ensure the chemically value added raw materials we source will comply with safe chemistry standards |

Ensuring we purchase and use safer chemicals in our operations, with the end goal of creating safer products and mitigating negative environmental impacts. |

Practices and processes within our facilities that identify hazards, guarantee safety of our teams, and ensure that chemicals are used in a correct way. |

Infrastructure and systems in place to treat and monitor effluent, reduce and mitigate potential risks, and validate our chemical management practices. |

Product Stewardship and Consumer Safety

Testing, verifying, and certifying that our products conform to international standards, national/regional regulations in our consumer markets, and brand-defined requirements. |

|

Monitoring of input chemical compliance and ZDHC wastewater compliance for 42% of our spend base. All embellishment subcontractors achieved minimum 94% compliance with ZDHC Chemical Gateway against MRSL Version 2.0. All applicable embellishment subcontractors fully complied with the ZDHC WWG. |

88% ZDHC MRSL compliance for chemicals used in Textile Production facilities. 94% Bluesign approved chemicals utilised in Textile dyeing operations. |

Compliance with local and national regulations for wastewater treatment (such as CEA limits, and BOI norms) Alignment with international effluent treatment standards (such as ZDHC WWG and parameters), where applicable. |

18 facilities meeting OEKO-Tex Standard one dye facility delivering Bluesign certified articles |

|

We strive to be compliant with existing regulations for safe chemical use, and proactive in assessing and anticipating upcoming chemical restrictions – through constant engagement with customers and suppliers, diligent monitoring of the regulatory environment, benchmarking against international standards, and exercising stringent controls at procurement.

We employ a hazard and risk-based approach to managing chemicals across all processes that involve chemicals; with a focus on safety of our teams and compliance of facilities.

Our responsibility in chemical-use extends to wastewater treatment and discharge from our wet-processing facilities. Effluent Treatment Systems are in place to effectively remove contaminants from wastewater before discharge, and rigorous monitoring of effluent quality ensures we meet the standards set by national regulations and international benchmarks, such as ZDHC Wastewater Guidelines, the SAC’s Higg Facility Environmental Module (FEM), and our own MAS scale (Environmental Calibration) Tool to verify effectiveness and successful implementation of Chemical Management Work Stream requirements.

With regard to our operations in Sri Lanka, all facilities within the MAS Fabric Park (MFP), directly discharge their wastewater to the MFP wastewater treatment plant. After undergoing secondary and tertiary treatment, wastewater from MFP is discharged into a surface water body.

All treated wastewater discharged strictly adhered to standard parameters set out by the Central Environmental Authority (CEA), and complied with norms set by the Board of Investment (BOI) or country applicable standard. Quarterly tests are conducted, and test reports are submitted to local authorities and other regulating bodies. Where applicable, they were also in alignment with international effluent treatment standards, such as ZDHC WWG and parameters. There were no incidents of non-compliance with ZDHC WWG discharge limits reported during the year 2023.

Ensuring the safety of our products has always been paramount. It is a fundamental component of our approach to product stewardship, which extends to responsible chemical use and our ambitious goal of creating sustainable products that are good for the wearer. This is why we take a long-term, strategic, and multifaceted approach to assessing and managing the health and safety impacts of our products and services.

With regard to chemical compliance at the output-level, we verify the safety of our products by adhering to brand and product-specific RSL requirements – which are cascaded to Tier 1 supply chain partners where applicable; and conducting rigorous finished-product testing through third-party laboratories (based on brand recommendations for sample selection, running bulks, and shades/styles).

As an apparel manufacturer, our role in supporting transparency and traceability across the value chain for raw materials, waste, and ethical business practices; empowers our customer brands to uphold their commitments and provide their consumers with accurate information to make informed decisions. We have adopted all necessary technical, chemical, and raw material related compliance factors in the sourcing and processing of our products.

This comprehensive management system, supported by robust policies and procedures, adequate resources, and routine monitoring, contributed to no reports of regulatory non-compliance, related to product safety, product labelling, or marketing communications, during the year.

For suppliers of fabrics, apparel embellishments, or chemicals; the risk of hazardous chemicals in products are controlled through ZDHC MRSL compliance assessment. We engage and work with all major raw material suppliers, and currently monitor input chemicals for approximately 42% of our spend-base against the ZDHC MRSL. Further RSL testing is also carried out for products and materials, if mandated by specific customer brands. Brand-specific RSL requirements are also cascaded to vendors and supply chain partners, and their confirmations, acknowledgements, and self-assessments enable compliance with the same.

Similarly, we ensure subcontractors are monitored against ZDHC MRSL in their production process, which serves to restrict most chemicals of concern and meet brand-specific requirements. Annual subcontractor forums are a key tool in raising awareness, communicating expectations, and ensuring compliance; while interim meetings serve as a monitoring tool to evaluate compliance and progress toward targets. When failures are found, or chemicals of concern likely to be regulated are identified, we work collaboratively with subcontractors to find safer alternatives.

The section on Our Products Changed for Good – Source Sustainably explores in detail, our commitment to working with suppliers to ensure compliance and promote sustainable practices.

Our Target for 2025:

Restoration of biodiversity in the space we occupy (25,000 acres)

2023: 51x (12,705 acres)

2022: 39x (9,651 acres)

Biodiversity represents the foundation of our planet’s health and well-being. This intricate tapestry, woven from countless species and their interconnected relationships, forms a myriad ecosystems on earth. Biodiversity plays a vital role in vital ecological processes, including air and water purification, nutrient cycling and climate regulation. Furthermore, it provides humanity with a wealth of resources, including food, medicine, and essential ecosystem services.

Acknowledging the impact of our operations on biodiversity through land-use change, we actively contribute to its conservation and restoration. Identifying this as a sustainability imperative, and initiating projects in 2016/17, biodiversity conservation is now an essential element of the MAS Plan for Change. Our commitment to Champion Biodiversity involves proactive engagement – as we pledged to restore habitats and enhance ecosystem services in an area 100 times larger than our physical footprint; embarking on an ambitious “Journey to 25,000 acres.” This initiative primarily aligns with SDG 15: Life on Land, which aims to protect, restore and promote sustainable use of terrestrial ecosystems, sustainably manage forests, combat desertification, and halt and reverse land degradation and biodiversity loss. Our biodiversity initiatives have expanded to cover coastal ecosystems, with conservation projects for mangrove and sea turtle habitats, and future efforts looking at coral reef ecosystems. These directly relate to SDG 14: Life Below Water, and Target 14.5 in particular – focused on the conservation of coastal and marine areas.

JOURNEY TO 25,000 ACRES

In 2023, we surpassed the 12,500-acre mid-way milestone, achieving 51% of our target for 2025, with an impressive 3,054 acres restored during the year, bringing the cumulative area impacted, to 12,705 acres.

Much of our impact is through direct and partnered conservation efforts (59%) and invasive species removal (24%) – both urgent priorities in our countries of operation, where rapid urbanisation and population growth are driving land-use change and biodiversity loss, while invasive species are threatening the balance of natural ecosystems.

Global restoration projects are a new avenue for impact; where MAS is leveraging its global presence and reach, to address urgent needs for biodiversity conservation in even more ecoregions. The Kenya Conservation Project, a collaborative initiative that commenced in 2022, has now contributed to preserving about 7,345 acres of critical habitat, by the end of 2023. The Project directly benefits 70 conservation members and indirectly supports approximately 190 households.

Our approach to biodiversity, initiated in 2017, began with a straightforward yet ambitious vision. Recognising that our facilities and built spaces across Sri Lanka and other countries occupy 251 acres of land, we acknowledged the need to compensate for the ecosystems we impacted. While none of our facilities operate in or adjacent to protected areas or areas of high biodiversity value, we committed to restoring and rehabilitating 100 times the area we occupy, amounting to a target of 25,000 acres.

To achieve this goal of restoring biodiversity in our countries or regions of operation, MAS has deployed six models to engage in habitat creation and conservation.

Selection of projects aligns with three key objectives.

Projects prioritise areas of high biodiversity value; home to a number of endemic, endangered, vulnerable, or threatened species. As our largest operational footprint is based in Sri Lanka, much of our work has focused on Sri Lanka’s biodiversity hotspots.

However, as our enterprise has expanded, so have our opportunities to make a positive change. Two of our most recent projects, are also our largest: A collaborative conservancy model implemented in Kenya’s Nairobi National Park Wildlife Dispersal Area – supporting wildlife migration in a region with the richest large-mammal biodiversity on Earth; and habitat restoration in Central Java, Indonesia – restoring ecosystems in one of the world’s largest rainforest areas.

None of our initiatives are carried out in isolation; instead, they often involve multiple stakeholders. Wherever possible, we actively engage in partnering with the people and organisations working on the ground. Their expertise, knowledge of the local context, and long-term involvement in the project area ensure the sustainability of our interventions.

We collaborate with partners, promote innovative techniques, and incorporate modern technologies or smart tools for scale, impact, efficiency, and reliability. Throughout project implementation, and after completion, we place significant value on monitoring and assessing impact. Our teams and partners carry out continuous monitoring to track progress during and after project completion, conduct impact evaluations, and work towards independent verification where possible.

In addition, local authorities and government bodies such as the Department of Forest Conservation and Department of Wildlife Conservation, are active stakeholders in most of our projects. Their involvement and oversight contribute to the effectiveness of our initiatives, and guarantee that all relevant regulations and standards are monitored and maintained.

Since 2017, MAS has engaged in and supported about 30 restoration projects with partners, resulting in the restoration of more than 2,000 acres.

Key long-term partners for ongoing projects, include the Department of Forest Conservation and the Department of Wildlife Conservation – apex national bodies in Sri Lankan tasked with conserving forests, preserving ecosystems, and protecting local flora and fauna; and the Sri Lanka Air Force – a pioneering partner that has supported the successful implementation of multiple aerial reforestation projects.

MAS also engages with a wide variety of other partners, either at Group-level, or facility-level. These include not-for-profit societies, foundations, and institutions, private-sector corporations, academic institutions, and other local authorities, community-based organisations, or grassroots initiatives working on the ground.

The Earth’s ecosystems that are already contending with a variety of anthropogenic impacts, are further at risk due to invasive species; which are affecting biodiversity, disrupting the ecological balance of fragile and protected regions, and have the potential to threaten human food security.

Our projects focus on areas of high biodiversity value, home to a number of endemic, endangered, vulnerable, or threatened species. We work with partners to carry out programmes for targeted removal of invasive species, long-term maintenance and restoration of natural vegetation, and enrichment planting that supports restoration of ecological balance.

Since 2017, we have completed projects in 1,905 acres, across seven of Sri Lanka’s protected conservation areas. As of 2023, we are implementing invasive removal projects covering 1,187 acres, in two additional national parks.

Udawalawe National Park has a unique history representing the cascading impacts of human activity and both the adaptability and fragility of nature.

Historically a riverine ecosystem with floodplains, forest, and scrub typical of the Country’s dry-zone; the area also comprised large swathes of grassland bearing testament to abandoned chena lands. Sri Lanka’s oldest form of slash-and-burn agriculture (chena cultivation) had given way to acres of Guinea Grass – a species introduced in the 1800s, as forage and fodder for livestock, which had subsequently naturalised and spread across most of the country. The grassland and floodplains presented ideal grazing and watering for herbivores, and attracted a sizable elephant population.

After construction of Udawalawe Reservoir, in the 1960s, a portion of the area was designated as a national park in 1972, to provide shelter and sanctuary for wildlife displaced by the dam and reservoir. Unfortunately, in the years that followed, much of the grassland came to be replaced by scrub as invasive alien species, such as Lantana camara and Eupatorium odoratum, took root. These fast-growing and highly-adaptable invasive species crowded out native vegetation, reduced forage for elephants and other fauna, and had a detrimental effect on native biodiversity.

In response, MAS, in collaboration with the Department of Wildlife Conservation and other stakeholders, launched a comprehensive invasive removal project in 2017. Since then, projects have cleared invasive Lantana camara from over 706 acres; paving the way for long-term health and resilience of the habitat. An ongoing project with the Federation of Environmental Organisations (FEO), in the nearby Lunugamvehera National Park, is similarly working to clear invasive species from 943 acres, while supporting livelihoods of local communities.

In 2023, to assess the project’s effectiveness, we commissioned an independent study, covering the project’s full extent (706 acres). The study was conducted by the Faculty of Science, University of Colombo, Sri Lanka.

The study commissioned by MAS, and ongoing research by other stakeholders, including the Department of Wildlife Conservation and local non-governmental bodies, are providing valuable information on how elephants and other large herbivores utilise these restored habitats; informing current and future conservation efforts.

Many of our planet’s natural ecosystems have been disturbed by human activity and resulting environmental changes, leading to biodiversity loss on a global scale. Our restoration projects utilise a variety of proven scientific techniques, based on needs of different regions, and the capacity of institutions and communities working on the ground.

Restoration methods vary from efficient and cost-effective aerial restoration for heavily degraded areas; to resource-intensive multistage methodologies such as replanting, community engagement, public awareness and education, and planning with local counterparts to develop and operationalise comprehensive conservation plans. Together, these projects aim to initiative, support, or accelerate recovery of disturbed ecosystems, and strengthen communities and institutions that function as environmental stewards.

RESTORING MANGROVES FOR COASTAL RESILIENCE

Coastal mangrove ecosystems are proving to be a vital resource in mitigating and adapting to the effects of climate change – by not only sequestering carbon, but also building resilience of coasts and their communities.

Mangroves are unique habitats that provide a multitude of benefits. Apart from protecting against coastal erosion, they also serve as nurseries for aquatic life; providing protected and nutrient-rich spawning and feeding grounds that boost biodiversity – this, in turn, enhances fish stocks that support local livelihoods. However, human activity has led to mangrove degradation, jeopardising these crucial benefits. This is why we have actively pursued mangrove restoration projects in Sri Lanka; restoring these biodiversity hotspots that are home to a large number of endemic species.

Having completed two projects spanning 56 acres, we are currently implementing partnered projects in 23.5 acres across three regions, and have plans in place to expand restoration efforts in 2024.

Our ongoing projects in Galle and Trincomalee have incorporated partnership with local authorities, active community engagement, education and outreach, and plans for long-term area management. The two projects are not only restoring essential habitats, they are also providing learning for future restoration projects, and creating community-based models for sustainable ecosystem management.

In Galle, the use of region-specific mangrove species, mangrove nurseries, and specialised planting-adaptations to support sapling establishment, have resulted in a remarkable 80% survival rate. In addition, local engagement, school-level awareness, welfare programmes, and financial incentives have motivated communities to actively engage in conserving their mangrove habitat. While an impact study has been planned to study the effectiveness of the project, teams on the ground are already seeing positive effects of community efforts, with elimination of illegal garbage dumping at the site. Similarly, the Trincomalee project has achieved 70% survival rate due to utilisation of site-specific species, careful consideration for soil structure and hydrology, and planting adaptations that enabled propagules to deal with tidal variations.

REFORESTATION OF GREEN CORRIDORS FOR ECOSYSTEM RESILIENCE

A partnership with one of the oldest nature protection societies in the world, is unlocking innovative new avenues for habitat restoration and resilience.

Continued commercialisation of land for agricultural use, has disrupted Minuwanella’s natural habitat and created isolated patches of forest, amidst stretches of tea and cinnamon plantations, which hinder the natural movement of species. Fragmentation of natural wilderness is an all too common occurrence in Sri Lanka that destabilises ecosystems and presents challenges for conservation efforts.

In response, MAS partnered with the Wildlife and Nature Protection Society (WNPS), through the WNPS Preserving Land and Nature (PLANT) project, in 2023. PLANT is an innovative and ambitious project that is leveraging corporate citizenship, philanthropy, community involvement, and a scientific approach to restoration; to establish and preserve green corridors in some of Sri Lanka’s most biodiversity-rich regions.

The MAS-WNPS-PLANT Minuwanella Reforestation Initiative is currently focusing on restoring 3.75 acres of forestland adjacent to Sri Lanka’s cultural and biodiversity-rich Peak Wilderness Sanctuary. The project, set to restore an additional 7.5 acres by 2025, contributes to PLANT’s vision for green links between fragmented patches of natural forest.

In 2023, the reforestation initiative cleared invasive species that had overtaken natural flora, planted native species, and involved communities at every step – from site preparation to planting. While still early into Phase 1, the project is already seeing positives; with a notable increase in the Hump-nosed lizard population, and further signs of recovery among other vital species like butterflies and frogs.

Our in-situ conservation projects are working to preserve biodiversity, safeguard natural ecosystems, and protect a number of species that are threatened by habitat-loss, human-animal conflict, and other anthropogenic impacts. We work with pioneering partners and promote holistic and innovative approaches to conservation that can have a lasting impact.

COLLABORATIVE CONSERVANCY MODEL TO PROTECT WILDLIFE MIGRATION

Community-based conservancy fostering coexistence between humans and wildlife around Kenya’s oldest national park.

The Kenya Conservation Project, a collaborative effort between MAS, The Wildlife Foundation (TWF), and the Naretunoi Community Conservancy; is achieving remarkable results in both conservation and community development.

The five-year partnership, initiated in 2022, will expand TWF’s successful conservancy model within the Nairobi National Park Wildlife Dispersal Area. The unique initiative builds upon TWF’s existing approach, which utilises a combination of financial and non-financial incentives to sustain conservation efforts. The project aims to encourage landowners and local communities to maintain open land corridors to allow the free movement of wildlife and livestock in the park’s outskirts, aiding both wildlife conservation and improved land-use practices.

By the end of 2023, the project has successfully preserved 7,345 acres of critical habitat. It directly benefits 70 conservation members and indirectly impacts an additional 189 households, while contributing to MAS’ target of restoring 25,000 acres of habitat.

The project’s integrated approach goes beyond conservation to empower communities, particularly women-led households, by diversifying income streams through sustainable use of natural resources. This reduces vulnerability and allows families to invest in education access for their children. The project’s emphasis on girls’ education is boosting secondary school completion rates, while the Conservation Education Centre nurtures young minds, building a future generation of environmental stewards and safeguarding indigenous heritage.

Collaboration between TWF and the Naretunoi Community Conservancy, fuelled by MAS’ support, is introducing a number of innovative approaches and contributing to real impact. The Biodiversity Conservation Lease Programme plays a vital role in strengthening conservation efforts and improving local well-being. By increasing household memberships in the lease programme, the project provides socio-economic benefits and educational opportunities within the Naretunoi Conservancy. Similarly, payments for ecosystem services and the establishment of biodiversity property rights are contributing to equitable benefits and sustainable cost-sharing models that would support conservation efforts in the long-term.

Our Target for 2025:

Reduction of our textile production water intensities

2023: 43% reduction

2022: 36% reduction

Our Commitment:

Achieve zero impact to MAS’ operations and mitigate negative impact to the environment and community.

^based on 2011 baseline

The Earth’s water resources face increasing pressure from population growth, the impacts of human development, and climate change induced drought, flood, and shifts in rainfall patterns. These factors are affecting water quality and contributing to water scarcity all across the globe.

For the apparel industry, water is a vital resource across the value chain – from raw material inputs, to manufacturing processes, and the aesthetics and functionality of finished products. It is essential to the success of our business, but also vital for the well-being of our people and the sustainability of our planet.

This is why safeguarding water is much more than an environmental responsibility for MAS. It is a business imperative that involves collaborative efforts with customers, partners, suppliers, and communities; investment in the capabilities, awareness, and engagement of teams; and continuous improvement of technologies and processes. In 2015, we set ourselves an ambitious target of reducing, by half, the water footprint of our most water-intensive production processes. This envisioned a massive technological transformation to adopt waterless dyeing techniques at scale. However, a number of factors have affected feasibility and limited their adoption. Therefore, our teams made a collective decision in 2022, to recalibrate our targets – focusing on a goal that, while still ambitious, would also be achievable.

SAFEGUARDING WATER FOR OUR OPERATIONS, COMMUNITIES, AND ENVIRONMENT

In 2023, our overall water efficiency remained strong, reflecting a 43.07% water intensity reduction in textile operations (textile manufacture and knitting) against the 2011 baseline. Despite lower production volumes and planned facility shutdowns for maintenance, we maintained a positive trajectory towards our 2025 goal. This significant achievement is testament to successful implementation of best-practices and process optimisation across our textile operations.

With regard to our apparel manufacturing operations in 2023; we achieved a 9.65% reduction in water intensity against the 2013 baseline, showing incremental year-on-year improvement. While this represents a much lower-impact segment of our operations, we continue to work towards internal operation-specific water-intensity targets. Ongoing initiatives for water-recycling, effective management and maintenance of HVAC infrastructure, and facility-level best-practices, are all contributing to long-term reduction in water intensity. Water recycling and reuse measures at our facilities continued to yield positive results, as we achieved a total water recycling amount of 94.9 ML during the year – up significantly from the previous year, and now equalling almost 5% of our total water withdrawal for the year.

Total water withdrawal for the year stood at 1,833 ML (megalitres), with majority of water coming from third-party sources: 57% from the National Water Resource Board through third-party purchases, and approximately 23% sourced from MAS Fabric Park (MFP) as an industrial park utility service provider. MFP’s industrial support infrastructure provides centralised water, power, steam supply, and effluent treatment services to businesses functioning in the zone. This plug-and-play model empowers facilities set up at the park, such as Methliya, Matrix, Trischel, Textprint, Texo, MAS Fabric Intimo, Thurulie, and Linea AITC, to focus on their core competencies and optimise production processes.

About 13% of our water withdrawal in 2023 came from groundwater sources (4% from dug wells and 9% from tube wells); 5% from recycled water; and 2% from other resources such as bowser-water, water-dispensers, and rainwater. All water withdrawal was carried out with necessary permits from local authorities, and stringent limits and controls for extraction were exercised. While groundwater usage declined in absolute terms during the year, there was a marginal increase from the previous year when considering share of the water-mix. Despite this, our ongoing efforts to reduce utilisation of groundwater have contributed to a steady year-on-year declines for the share of groundwater in our water-mix during the past five years.

Our textile production operations account for 47% of water-use. This represents a high priority segment; as wet operations in the industry are heavily dependent on freshwater, involve the use of chemicals and other contaminants, and necessitate stringent and effective effluent treatment.

While our apparel manufacturing operations account for 53% of water-use; utilisation for HVAC cooling towers, sanitation, and other domestic purposes involves minimal water-loss due to evaporation and consumption. The majority of water withdrawn is released, after suitable treatment, and can be considered a recoverable return flow – maintaining water availability for ecosystems, industries, and communities downstream.

Metrics and percentages represented below are based on 2023 figures. Water source and share of water-use are largely unchanged year-on-year, while volume of water consumption is directly associated with production volumes and scale of our operations.

Scope |

Water withdrawal (ML) |

Primary uses |

Conservation measures |

|

| Apparel manufacturing (cut and sew operations) | Third-party

water (79%) Groundwater (13%) |

978.66 (53%) | Domestic:

Consumption, cooking, sanitation, landscaping. Industrial: HVAC |

|

| Textile production (textile manufacture and knitting) | 853.89 (47%) | Industrial

(wet processing): Pre-treatment, dyeing, printing, rinsing and washing. |

|

| Main City Water Line | 1,091,523.5 |

| MAS Fabric Park Water Line | 449,051.2 |

| Dug Well | 86,081.6 |

| Tube Well | 172,182.2 |

| Bowser | 33,662.5 |

| Dispenser | 50.2 |

| Rain Water | 2,167.0 |

| Recycled Water | 94,904.6 |

To identify water risk in the areas we operate, we employ a standardised risk-based approach to assessing and managing water-related issues. Internally, we identify facility risks through a Water Risk Assessment, gathering inputs primarily from risk-filter tools made available by the World Wide Fund for Nature (WWF). These tools enable our teams to analyse and evaluate potential physical, regulatory, and reputational risks (related to water) for operations, at a facility-level. Risks are evaluated on an annual basis, and assessments have been carried out for the past two years.

At Group-level, we set annual normalised water targets that are cascaded to SBUs and individual divisions. This systematic approach is designed to efficiently reduce overall water intake while promoting sustainable utilisation practices. Employee engagement is a key factor in working toward our targets and successfully implementation of our strategies to safeguard water; including water reuse and recycling. We utilise water-intensity targets specific to our operations – for textile production (measured in litres per-kg) and apparel manufacturing (measured in litres per-head per-shift), and benchmark our progress against these targets.

Our efforts to reduce reliance on freshwater have involved use of greenwater (harvested rainwater) and scaling up MAS’ greywater utilisation through innovative treatment, recycling, and reuse, where possible. Some apparel facilities incorporate on-site Sewage Treatment Plants (STPs) for wastewater treatment, with treated greywater being reused for landscaping, sanitation systems, and other purposes. A stand-out example is our Linea Aqua facility in Hanwella – Sri Lanka, where a two-step wastewater treatment process incorporates further water purification via Reverse Osmosis (RO). This recycled water is then used in cooling towers and for flushing toilets.

Recognising the importance of water resources to the communities around our operations, MAS implements a number of impactful water-related projects aimed at improving accessibility and enhancing the overall quality of water resources in our areas of operation. This proactive engagement, especially in water-risk zones, strengthens ties between facilities and the community and contributes to sustainable water management at a broader level.

Climate change, global warming, and resultant shifts in weather are having an unquestionable impact on the incidence of drought and flood across the globe. Our operations are partially affected during periods of drought or flooding – with the biggest impact on processes that are highly sensitive to water quality.